Product Demonstration

Making Manufacturing Smarter

LinkCycle helps reduce manufacturing costs without having us step foot onto the plant floor–no more hardware, no more audits.

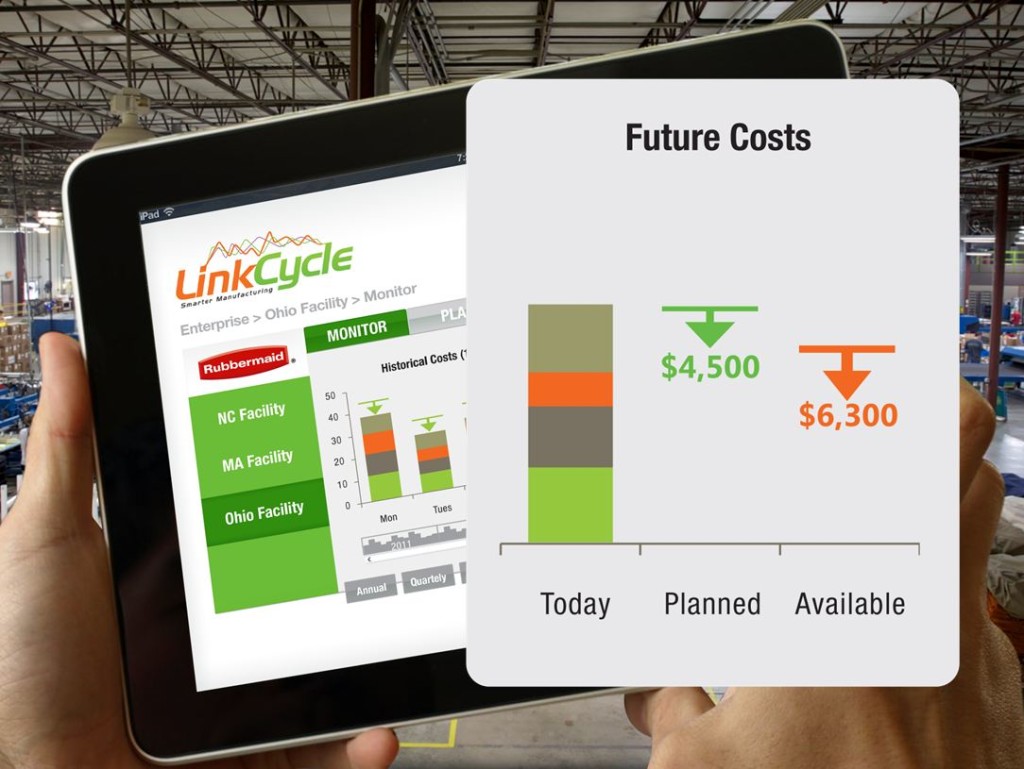

The plant manager can walk through the plant with his iPad and identify how energy is flowing through the machines in his facility, and see opportunities to reduce production costs. The below screenshots show how LinkCycle works.

Plan Tab – By identifying the energy cost for all the production lines, LinkCycle identifies inefficiencies. Select one of four strategies to reduce production costs for the day. These include scheduling, machine utilization, process control, and equipment upgrades.

Example Strategy: Scheduling – In this scheduling example, by moving ‘Waste Can’ production to the night shift, when the electricity price is lower, $11,000 can be saved today.

Monitor Tab – Every day, the plant manager can see (1) Historical Costs, and (2) Future Costs.

Example: Historical Costs – Under Historical Costs, the energy cost for each production line is shown, identifying which products are driving total costs for that facility, as well as how much was saved by LinkCycle.

Example: Future Costs – Under Future Costs, the plant manager can see expected energy costs for that day, how much he plans to reduce it by, as well as how much available savings there are.

Thank you for having a look at our product demonstration. Please contact a sales representative now for a data collection template, or to conduct a pilot on one of your facilities.